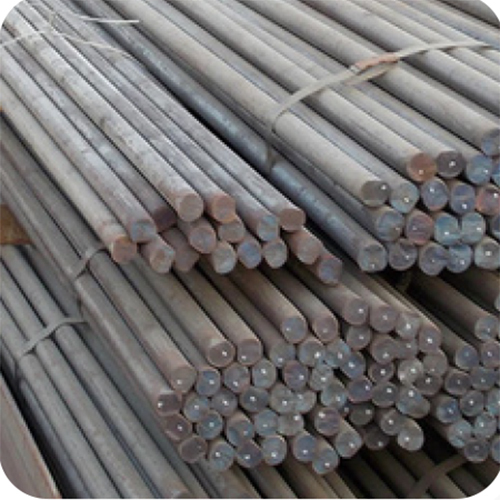

MS ROUND BAR

MS ROUND BAR Specification

- Installation Type

- Direct installation, welding, or bolting

- Purity

- Commercial quality mild steel

- Material Grade

- IS 2062, ASTM A36, EN8, or as specified

- Diameter

- 6mm to 200mm or customized Millimeter (mm)

- Form

- Solid Bar

- Color

- Black or Grey (as per standard MS finish)

- Application

- Structural support, Shaft, Machinery

- Usage

- Ideal for forging, construction frameworks, and machine parts

- Features

- Excellent weldability, Good machinability, Uniform cross-section

- Machines Type

- Compatible with cutting, welding, and shaping machines

- Product Type

- MS Round Bar

- Main Material

- Mild Steel

- Surface Treatment

- Hot Rolled

- Size

- Customizable as per requirement

- Feature

- High strength, Durable, Corrosion resistant

- Shape

- Round

- Packing Details

- Standard bundle packaging or as per customer request

- Length

- Typically 6 meters or customized lengths

- Yield Strength

- Minimum 250 MPa for IS 2062 grade

- Standards

- IS, ASTM, EN Standards

- Hardness

- 125180 HB (approx., depends on grade)

- Customization

- Available for size, length, and grade

- Tensile Strength

- Approx. 400 550 MPa (varies by grade)

- Edge Type

- Mill finish ends or customized

MS ROUND BAR Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Supply Ability

- 1000 Kilograms Per Month

- Delivery Time

- 7 Days

About MS ROUND BAR

Versatile Applications Across Industries

MS Round Bars serve a wide range of industries including construction, engineering, manufacturing, and fabrication. Their strength, durability, and machinability make them suitable for structural supports, machine shafts, and frameworks. The customizable dimensions and grades ensure precise adaptation to your specific project needs.

Customizable to Project Requirements

Whether you need specific lengths, diameters, or material grades, MS Round Bars can be tailored to your requirements. The flexibility extends to surface treatment, edge type, and packing, allowing suppliers in India to meet diverse customer demands from dealers and distributors to individual project clients.

Compliant With International Standards

Manufactured to IS, ASTM, and EN standards, MS Round Bars guarantee reliable performance and quality. The standardized production ensures consistent mechanical properties, including high tensile and yield strengths, making them dependable for critical applications like forging, welding, and direct installations.

FAQ's of MS ROUND BAR:

Q: How are MS Round Bars typically installed in construction or machinery projects?

A: MS Round Bars can be directly installed, welded, or bolted, depending on the project's requirements. Their solid form and uniform cross-section ensure robust support in frameworks and ease of integration with machinery parts.Q: What customization options are available for MS Round Bars?

A: Customization is available for length, diameter, material grade (such as IS 2062, ASTM A36, EN8), and edge finish. Surface treatment and packaging can also be tailored to meet customer specifications or unique project demands.Q: What are the main benefits of using MS Round Bars in structural projects?

A: MS Round Bars offer high strength, durability, and excellent weldability. They provide reliable load-bearing capacity, corrosion resistance, and adaptability for cutting, shaping, and forming, which make them valuable for structural and machine component applications.Q: Where are MS Round Bars most commonly used?

A: These bars are frequently used in forging, construction frameworks, structural supports, machinery parts, and shafts. Their versatility makes them suitable for projects from manufacturing plants to civil infrastructure across India.Q: What is the typical process for ordering customized MS Round Bars?

A: Customers can specify requirements such as length, diameter, grade, and surface finish when placing orders with suppliers, dealers, or wholesalers. The manufacturer then produces and packages the bars as per the agreed specifications.Q: When should I consider using a specific grade, like IS 2062 or ASTM A36, for my application?

A: The choice of grade depends on mechanical requirements like strength, hardness, and application environment. IS 2062 is common for structural uses, while ASTM A36 or EN8 may be selected for higher mechanical demands or specific industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in STRUCTURAL PRODUCTS Category

MS BEAM (ISMB & NPB)

Price 53 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Main Material : Mild Steel (MS)

Surface Treatment : Hot Rolled

Shape : IBeam / HBeam

Color : Grey, Natural finish

MS ANGLE

Price 45 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Main Material : Mild Steel

Surface Treatment : Polished

Shape : L Shaped

Color : Silver

MS SQUARE BAR

Price 46 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Main Material : Mild Steel

Surface Treatment : Polished

Shape : Square

Color : Grey

MS FLAT

Price 51 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Main Material : Mild Steel

Surface Treatment : Polished

Shape : Flat Bar

Color : Grey

Send SMS

Send SMS